RHEO AI Smart Operational Platform helps major industrial manufacturers reduce labor cost while simultaneously improving customer service levels

– ABSTRACT

A division of one of the top residential Windows and Doors manufacturing conglomerate was experiencing increasing Labor Costs, while daily throughput remained flat and on-time Customer Service levels were deteriorating. To improve service levels and reduce labor cost, the business needed to quickly understand the primary factors impacting performance of the glass cut process and the specific improvements required to improve performance rapidly.

THE OVERVIEW

- Labor costs were increasing, and on-time customer delivery was declining due to the extremely complex interactions of production scheduling, employee turnover, labor rate increases, and equipment unplanned downtime.

- Management relied on tribal knowledge and experience to drive process improvements.

SCENARIO

In a Windows and Doors manufacturing business, the glass cut process is critical, as it provides glass to the insulated glass (IG) assembly lines, which are then mounted on frames to produce windows.

If the glass cut line does not produce the required demand, it negatively impacts the daily capacity of multiple automatic and manual IG assembly lines. Also, as a result of unplanned equipment downtime, and high employee turnover, the business was experiencing insufficient demand fulfillment.

If the glass cut line does not produce the required demand, it negatively impacts the daily capacity of multiple automatic and manual IG assembly lines. Also, as a result of unplanned equipment downtime, and high employee turnover, the business was experiencing insufficient demand fulfillment.

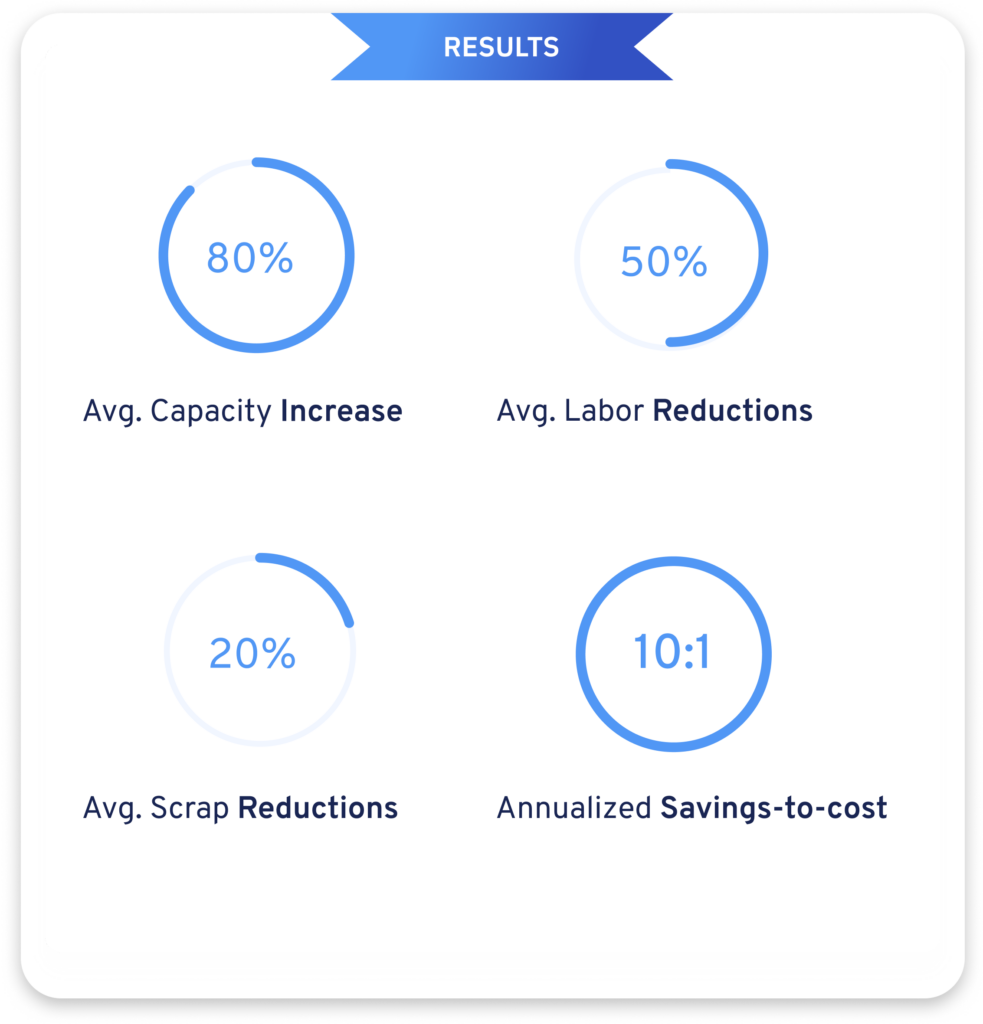

The glass cut process consists of :

1. A robotic glass sheet pick & place

2. An automatic multi-glass pane scoring based on a yield optimization model

3. Manual glass pane break-out

4. Glass placement in a designated location in a transportation cart.

2. An automatic multi-glass pane scoring based on a yield optimization model

3. Manual glass pane break-out

4. Glass placement in a designated location in a transportation cart.

THE CHALLENGE

- Complex multi-variant process difficult to optimize using traditional improvement tools and techniques

- Translate qualitative opinions to quantitative facts and data

Data related to equipment downtime was readily available, but the business did not know the downtime root causes. Also, the process optimization complexity is amplified by mixed model batch production scheduling which include variations in glass cut size, thickness, and grade coupled with varying seasonal demand cycles. Optimizing these types of multi-variate processes are extremely complicated to do with traditional cycle time and takt time analysis.

THE SOLUTION

- Translated complex multi-variate process performance data to simple process improvement insights empowered process owners to manage, hypothesize and drive improvements

RHEO AI Smart Operational Platform was deployed to automate data collection, analysis and process visualization using cameras and sensors. The RHEO platform’s integrated intelligence capabilities enabled the process managers, supervisors, leads, and line operators to quantify inefficiencies, in addition to automatically providing real-time identification and prioritization of root causes impacting process performance. This, in-turn, facilitated quick decisions on the actions required to improve performance.

THE RESULTS

- The RHEO system identified EBITDA labor savings (including Overtime) of over Six Figures in the first two weeks of introducing the RHEO system. The manufacturer is currently deploying the RHEO system for the glass-cutting process across several of their plants.

RHEO AI Smart Operational Platform helps major industrial manufacturers to improve Employee Satisfaction and Reduce Overtime Cost.

– ABSTRACT

A division of a one of the top residential Windows and Doors manufacturing conglomerate was experiencing excessive labor overtime in their insulated glass (IG) assembly process, resulting in low Employee Satisfaction, high Employee Turnover, and increasing Labor Cost. To rapidly turn-around this undesired situation, the business needed to quickly understand the root causes impacting the work center capacity and disproportionate overtime hours.

THE OVERVIEW

- Employee satisfaction was rapidly declining due to excessive overtime requirements to compensate for the lack of efficient and effective work-cell performance.

- Management relied on tribal knowledge and experience to drive process improvements.

SCENARIO

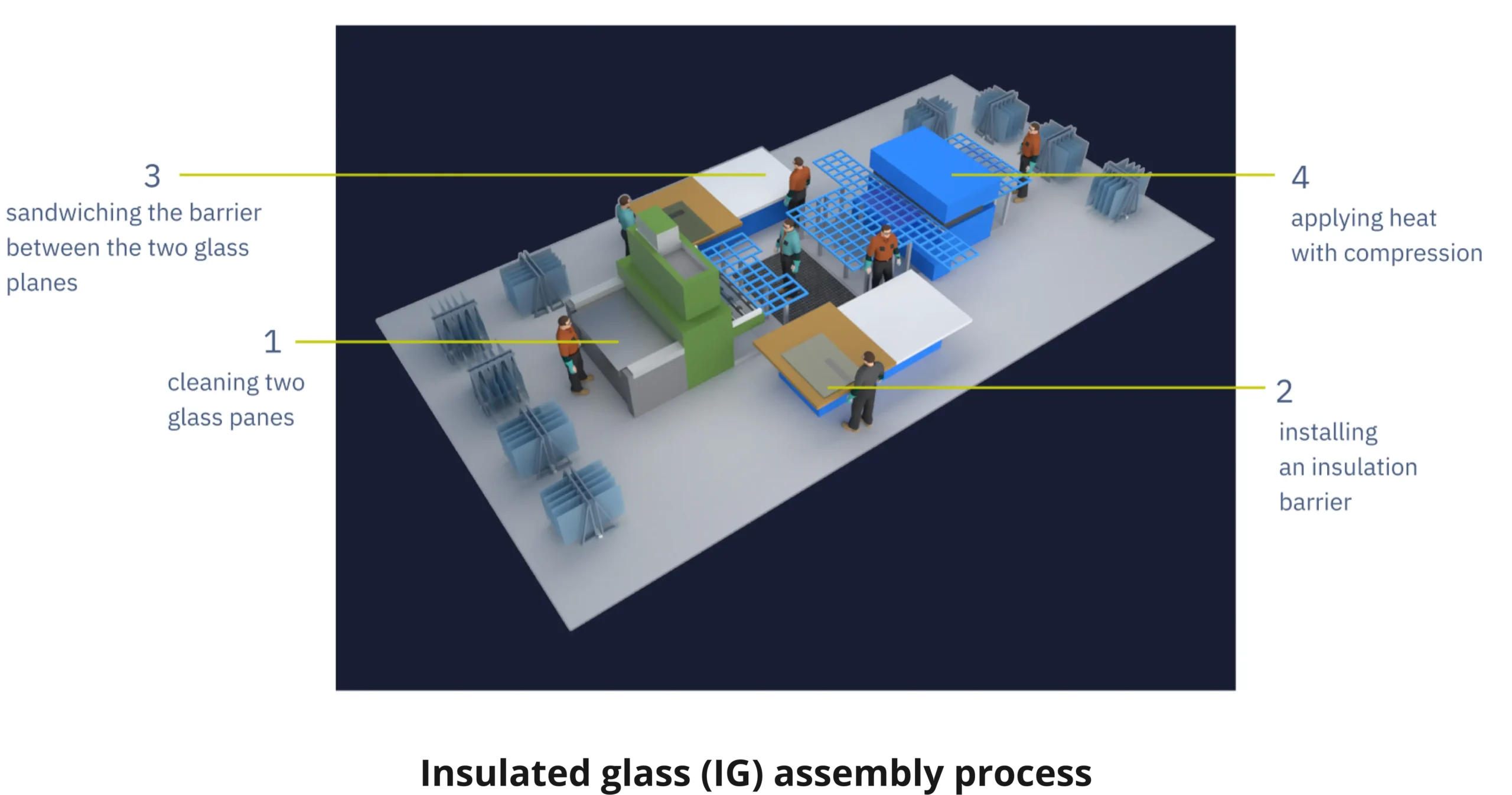

The insulated glass (IG) assembly process consists of four (4) primary operational steps. These steps include:

1. Cleaning two glass panes

2. Installing an insulation barrier

3. Sandwiching the barrier between the two glass planes

4. Applying heat with compression

2. Installing an insulation barrier

3. Sandwiching the barrier between the two glass planes

4. Applying heat with compression

Since homes have a variety of window and door sizes, the manufacturing processes must be setup to simultaneously run mixed model sizes. The processes must be highly synchronized in order to flow together at the exact time to assemble the final product.

THE CHALLENGE

- Time Studies generate only sample data and hence missed vital information and variations

- Time studies tend to bias against the cumulative effects of the ‘insignificant few’ root causes

An IG assembly area essentially supplies glass to all final product assembly lines and hence is typically the bottleneck in the overall product assembly process. As a consequence, upstream delays due to material shortages, resource deficiencies and unplanned downtime, causes capacity constraints on the entire assembly line. This in-turn affects customer satisfaction levels (due to delayed product shipment) and employee satisfaction levels (due to excessive demand for over-time hours).

THE SOLUTION

- Rheo provided process owners with prioritized improvement insights.

- Rheo empowered process owners with the knowledge to manage and drive improvements.

RHEO AI Smart Operational Platform was deployed to automate data collection, analysis and process visualization. The system with its ability to continuously monitor was able to measure and account each and every inefficiency incidence, including those that typically get deemed to be insignificant. As a consequence of the inherent continuous and exhaustive nature of the RHEO platform to identify root causes, the platform was able to recognize the effect of lack of steady supply of glass upstream in the process, leading to a re-allocation of resources, thereby improving the Units Per Worker Hour (UPWH) dramatically.

THE RESULTS

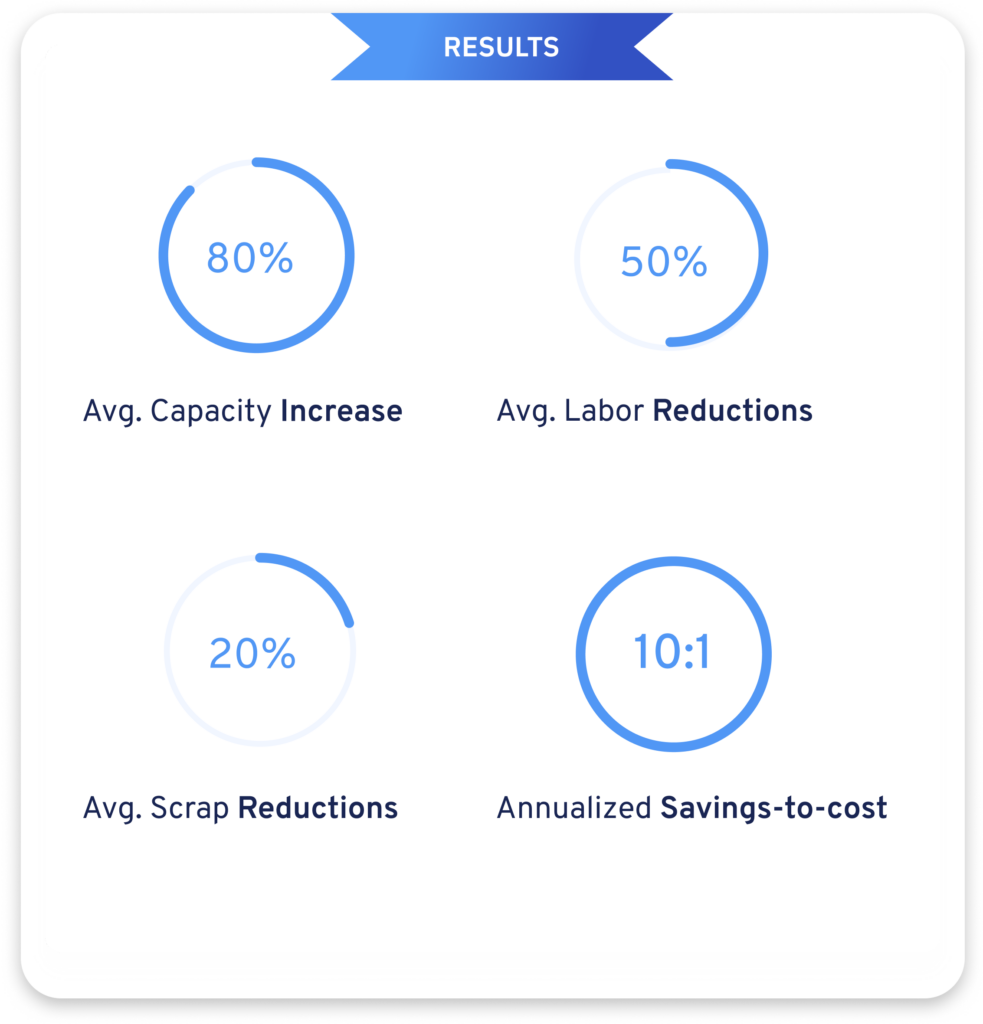

The pilot which lasted for a month, identified the following benefits:

- Management – Improved productivity resulted in Six Figure EBITDA labor savings of across two lines.

- Employees – Need for overtime was significantly reduced. Performance-based bonuses compensated for the overtime work loss resulting in increased Team morale (increased pay and improved work life balance).

- Customer – On-time customer delivery was consistently achieved without undue effort and additional planning.

Laminated Glass Manufacturer

RHEO AI Smart Operational Platform helps major US Laminated Glass manufacturer increase production line capacity and reduce labor costs

– ABSTRACT

- A US leader in Laminated Glass manufacturing needed to increase capacity to satisfy customer demand while simultaneously improving labor productivity

– CHALLENGES

- The operation’s team lack visibility into the process bottlenecks and constraints

- Production dashboards were not in place to provide process performance and improvement insights

- Supervisors were looking to management to provide operational improvement direction instead of seizing ownership and driving continuous improvement initiatives

- Overtime was being used to achieve customer service commitments

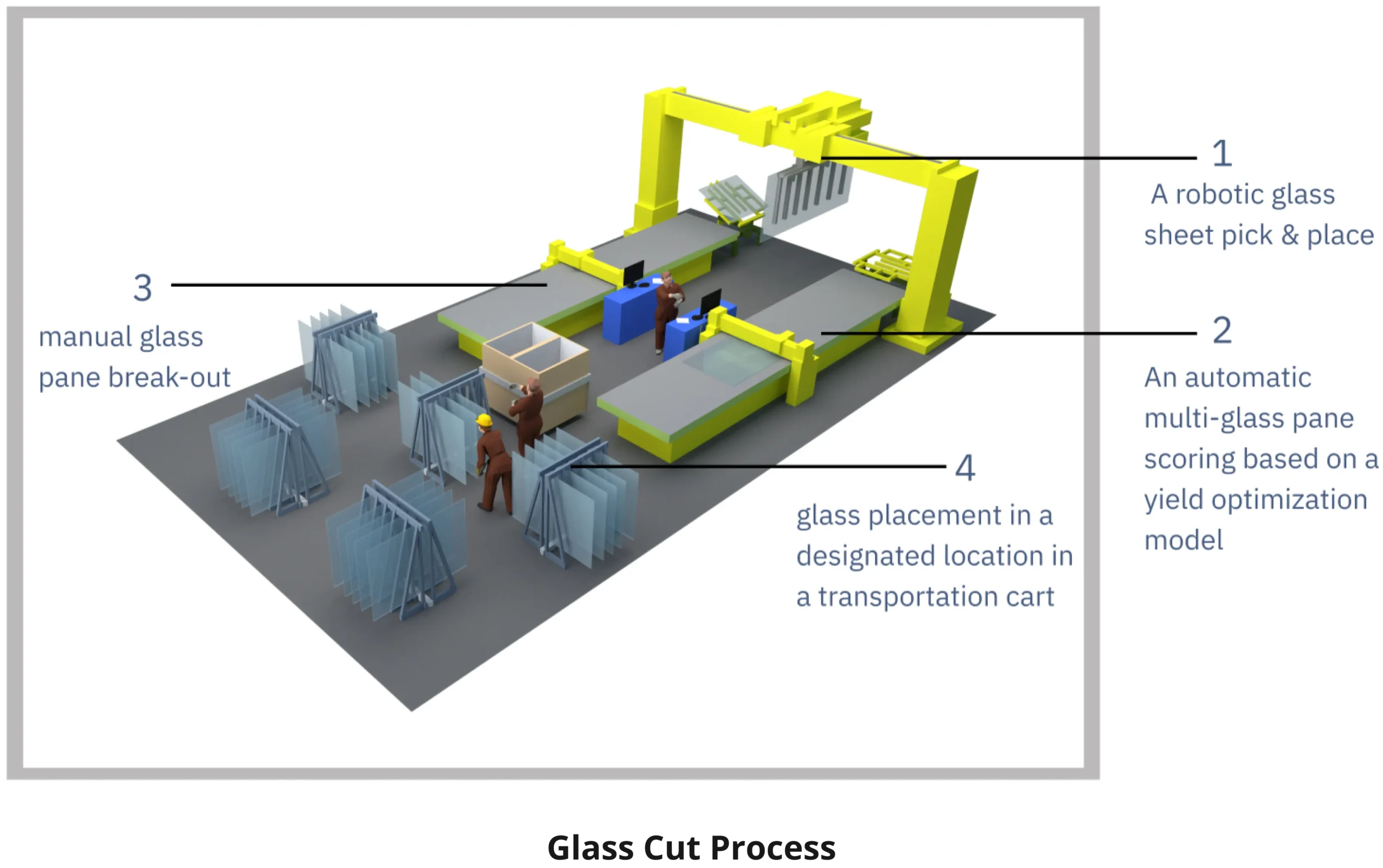

– RESULTS

- Realized a 97% increase in daily units

- Increased employee job satisfaction

- Supervisors were looking to management to provide operational improvement direction instead of seizing ownership and driving continuous improvement initiatives

- Supervisors have embraced the new empowerment and are using the RHEO system to identify, prioritize, implement and sustain process improvements

Aerospace Manufacturer

RHEO AI Smart Operational Platform helps major Aerospace manufacturer increase overall equipment effectiveness and reduce overtime labor cost

– ABSTRACT

- A High Mix Low Volume (HMLV) sheet and plate polishing company servicing the Aerospace industry was experiencing process efficiency challenges resulting in longer customer lead times, higher labor costs and declining financial margins

- To improve the process efficiency and financial performance, the business needed to quickly understand the primary factors impacting the operational performance while simultaneously deploying rapid improve initiatives

– CHALLENGES

- The operational team was lacking an Operational Management System (OMS) to proactively and adaptively address inefficiencies to improve performance

- Overtime was being used to achieve on-time customer service commitments

– RESULTS

- Reduced overtime by greater than 85% in Forming, Grinding and Polishing in 6 weeks of deployment

- Achieved $455k EBITDA savings in 6 months

Windows and Doors Manufacturing Conglomerate

RHEO AI Smart Operational Platform helps major industrial manufacturer reduce labor cost in glass cutting while simultaneously improving customer service levels

– ABSTRACT

- A division of one of the top residential Windows and Doors manufacturing conglomerate was experiencing increasing labor costs, while daily throughput remained flat and on-time customer service levels were deteriorating

- To improve service levels and reduce labor cost, the business needed to quickly understand the primary factors impacting performance of the glass cut process and the specific improvements required to rapidly improve performance

– CHALLENGES

- Extremely complex process interactions between production scheduling, multiple manufacturing departments and shipping

- High employee turnover and absenteeism

- Increasing labor rates

- Increasing unplanned equipment downtime

- Translation of managements qualitative opinions to quantitative facts and data

– RESULTS

- Identified EBITDA labor savings of over Six Figures in the first two weeks of introducing the RHEO system

- Manufacturer is currently deploying the RHEO system across all of their plants

Aerospace Manufacturer

RHEO AI Smart Operational Platform helps major industrial manufacturers reduce labor cost while simultaneously improving customer service levels

– ABSTRACT

- A sheet and plate grinding department was struggling with characterizing job efficiency and margin performance

- The business needed to move quickly to identify specific actions necessary to improve operational performance and increase EBITDA

– CHALLENGES

- Time standards were incomplete and inaccurate

- Production dashboards were not in place to provide machine or operator in-process performance and improvement insights

- Supervisors were not given process ownership and empowerment to drive continuous improvements

– RESULTS

- Reduced material scrap by 3%

- Increased labor productivity by 62%

- Supervisors have embraced the new empowerment and are using the RHEO system to identify, prioritize, implement and sustain process improvements

Laminated Glass Manufacturer

RHEO AI Smart Operational Platform helps major US Laminated Glass manufacturer increase production line capacity and reduce labor costs

– ABSTRACT

- A US leader in Laminated Glass manufacturing needed to increase capacity to satisfy customer demand while simultaneously reducing labor costs

– CHALLENGES

- The operation’s team lack visibility into the process bottlenecks and constraints

- Supervisors were looking for management to provide operational improvement direction instead of seizing ownership and driving continuous improvement initiatives in their areas of responsibility

- Overtime was being used to achieve customer service commitments

– RESULTS

- Realized a 97% increase in daily units in the first 3 weeks of deployment

- Increased job satisfaction through employee engagement

- Supervisors have embraced the new empowerment and are using the RHEO system to identify, prioritize and implement rapid process improvements

Aerospace Manufacturer

RHEO AI Smart Operational Platform helps major Aerospace manufacturer increase overall equipment effectiveness and reduce overtime labor cost

– ABSTRACT

- A sheet and plate polishing company servicing the Aerospace industry was experiencing machine efficiency challenges and lacked the operational systems to provide real-time process improvements insights

- To improve machine efficiency and control cost, the business needed to quickly understand the primary factors impacting performance of each department and determine the specific improvements required to rapidly improve performance

– CHALLENGES

- The operation’s team was lacking an Operational Management System (OMS) to proactively and adaptively address inefficiencies to improve performance

- Overtime was being used to achieve on-time customer service commitments

– RESULTS

- Reduced overtime by greater than 85% in Forming, Grinding and Polishing

- Achieved $455k EBITDA savings in 6 months

Windows and Doors Manufacturing Conglomerate

RHEO AI Smart Operational Platform helps major Window and Door manufacturer to improve Customer Ontime Delivery and Operational Performance

– ABSTRACT

- A high-volume Windows and Doors conglomerate’s largest business unit was experiencing surging demands, employee turnover and shortages, and increasing customer lead-times

- The business operates on a 24-hour schedule with all shifts comparatively planned and staffed

- To overcome the capacity and customer service level headwinds, the businesses needed to quickly scale process improvement initiatives across the business utilizing production staff

– CHALLENGES

- Supervisors lack the vital process information to quickly identify and prioritize improvement opportunities

- Daily units per day was 18% lower than established business objectives

- Multiple production lines making similar products were functioning as silos with suboptimal standardization and cross learning

– RESULTS

- Supervisors – Led the continuous improvement efforts to unlocked capacity in their responsible areas with minimal support from the continuous improvement team and management

- Manufacturing – Realized a 35% increase in daily units on three production lines in a three (3) week period

- Plant – Significantly reduced day-to-day throughput variation across shifts and lines

Aerospace Manufacturer

RHEO AI Smart Operational Platform helps major Aerospace manufacturer increase overall equipment effectiveness and reduce overtime labor cost

– ABSTRACT

- A 40-year-old privately held company which provides precision grinding and polishing services to the aerospace industry was experiencing declining overall equipment effectiveness, increasing overtime cost and lacked the operational systems to provide real-time information on the business performance

- The business needed to quickly understand the primary factors impacting the grinding and polishing processes and implement specific improvement actions to rapidly improve performance

– CHALLENGES

- The operational team was lacking a real-time Operational Management System to proactively and adaptively address inefficiencies and drive daily incremental improvements

- Operational information did not provide department, machine or operator in-process performance and real- time actionable improvement insights

– RESULTS

- Reduced overtime cost by 95%

Windows and Doors Manufacturing Conglomerate

RHEO AI Smart Operational Platform helps major industrial manufacturers to improve Employee Satisfaction and Reduce Overtime Cost

– ABSTRACT

- A leading manufacturer of windows and doors needed to grow capacities to support the surging building market demand

– CHALLENGES

- Space limitations and long machine lead times are preventing the addition of new production lines to support the capacity increases

- Supervisors were slow to embrace kaizen improvement events to identify bottlenecks in the process

- Production line output was 150-200 units/ shift lower than their parent plant

- Travel during Covid was limited which prevented the team from visiting the parent facility to identify the flow differences

- Vital statistical information needed for decision making was difficult to obtain

– RESULTS

- Supervisors – Supervisors started identifying bottlenecks and holding mini experiments to improve the processes

- Manufacturing – Realized a 38% increase in daily units in three production lines

- Financial – Daily revenue increased 8%

Windows and Doors Manufacturing Conglomerate

RHEO AI Smart Operational Platform helps major industrial manufacturers to improve Employee Satisfaction and Reduce Overtime Cost

– ABSTRACT

- A division of a one of the top residential Windows and Doors manufacturing conglomerate was experiencing excessive labor overtime in their insulated glass (IG) assembly process, resulting in low employee satisfaction, high employee turnover, and increasing labor cost

- To rapidly turn-around this undesired situation, the business needed to quickly understand the root causes impacting the work center capacity and disproportionate overtime hours

– CHALLENGES

- Process historical performance was based on sample data and hence missed vital information and variations

- Process observations tended to bias against the cumulative effects of the ‘insignificant few’ root causes

- Management relied primary on qualitative tribal knowledge and experience to decided on process improvement initiatives

– RESULTS

- Management – Improved productivity resulted in Six Figure EBITDA labor savings across two production lines

- Employees – Need for overtime was significantly reduced

- Customer – On-time customer delivery was consistently achieved without undue effort and additional overtime cost