-

Rheo has paid for its investment many times over already. Its changed the way we approach problems and solve them. Our response times are quicker, teams collaborate more seamlessly and decisions are backed by data.

JR Minnich, Vice President of Operations - Northeast, MITER Brands -

We initially adopted Rheo for tracking and improving Production flow but quickly discovered the system was capable of much more. One year on, Rheo is now an integral part of our operations. From Production tracking to Training development, the system continues to deliver for our team. The support from the Rheo team is world class and we believe our partnership with them will help lead us to the next level in manufacturing.

Timothy Kaiser, Plant Manager, Cardinal LG. -

Integrating Rheo into our manufacturing operations has been a groundbreaking enhancement. The AI-driven camera system has given us real-time visibility into our production lines, allowing us to identify inefficiencies and optimize workflows like never before.

Abhijeet Joshi, Vice President of Operations, MITER Brands. -

Aside from the significant improvements in Cost Savings and Customer Satisfaction, Rheo improves the day-to-day work experience across the organization, from the Executive to the Line Operator.

Mario Robles, President, Global Metal Solutions, Irvine.

can do for you

IMPROVEMENTS

Accelerate, sustain, and scale shop floor improvements with Rheo’s Experiment module.

Compliance and Audit Workflows

One unified platform for multiple compliance and audit workflows.

SPOTLIGHT

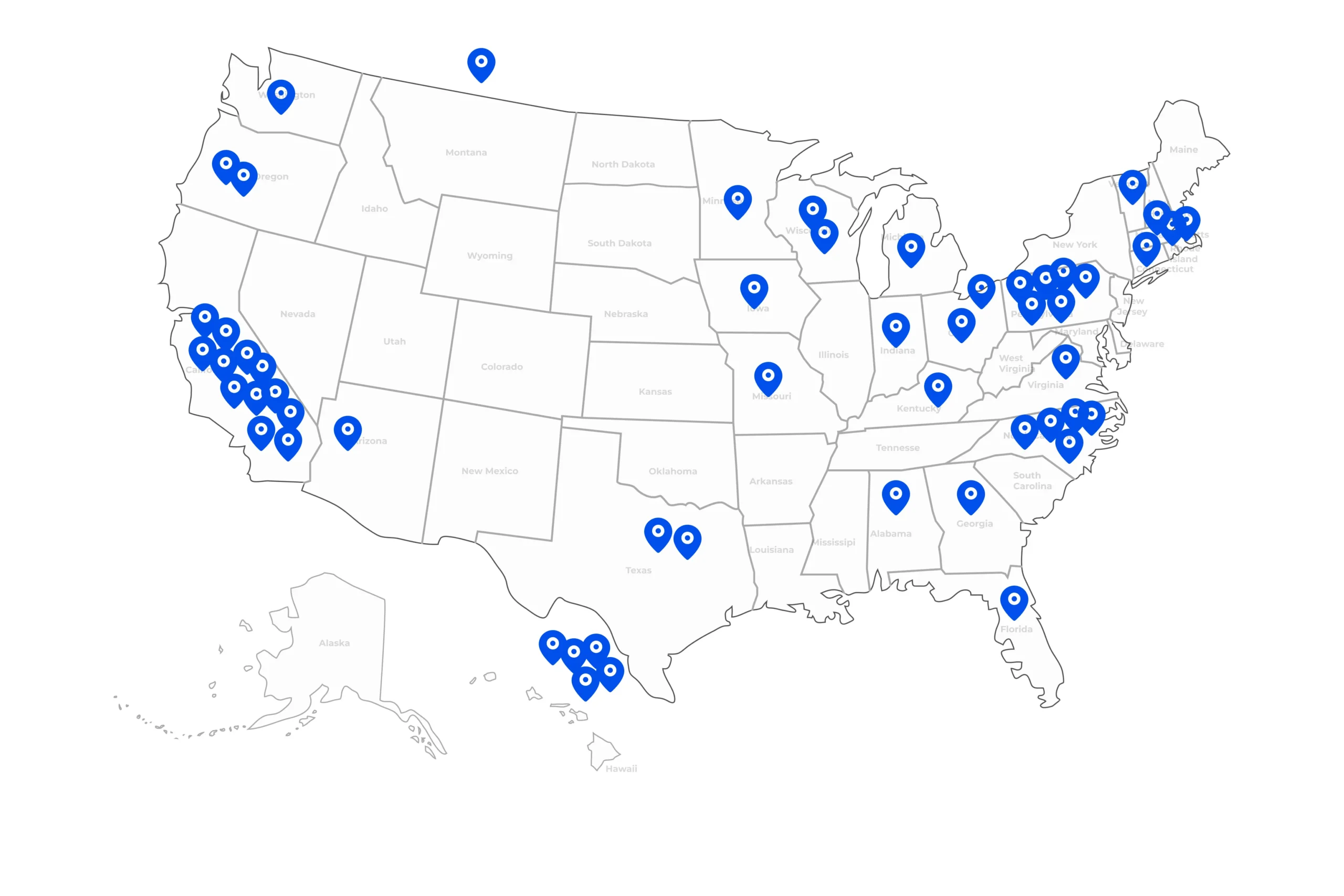

across 45 facilities and growing.

Increase

Reduction

to-Cost

Savings