Improvements

Accelerate, sustain and scale

Improvements on the Shop Floor.

-

Rheo has not only improved our production performance but also the process of process Improvements, transforming what was once a costly and time-consuming effort into a streamlined and efficient operation. It has made continuous improvement more accessible and effective for our team.

Ryne Crabb, Director of Operational Excellence, Miter Brands -

Rheo has empowered our team to make data-driven decisions that drive continuous improvement. It is quickly becoming an essential tool in optimizing our operations!

Abhijeet Joshi, Vice President of Operations, MITER Brands. -

Rheo is a comprehensive solution for Industrial and Continuous Improvement Engineers, providing built-in tools to analyze workflows, optimize processes and create standard work - fundamental to any continuous improvement journey. Driven by a strong customer-centric approach, the company focuses of innovation and enhancing its platform to be the ultimate resource for Lean organizations striving for operations excellence.

Nithin Varkey, Manufacturing Manager, MITER Brands.

HOW DOES

IT WORK?

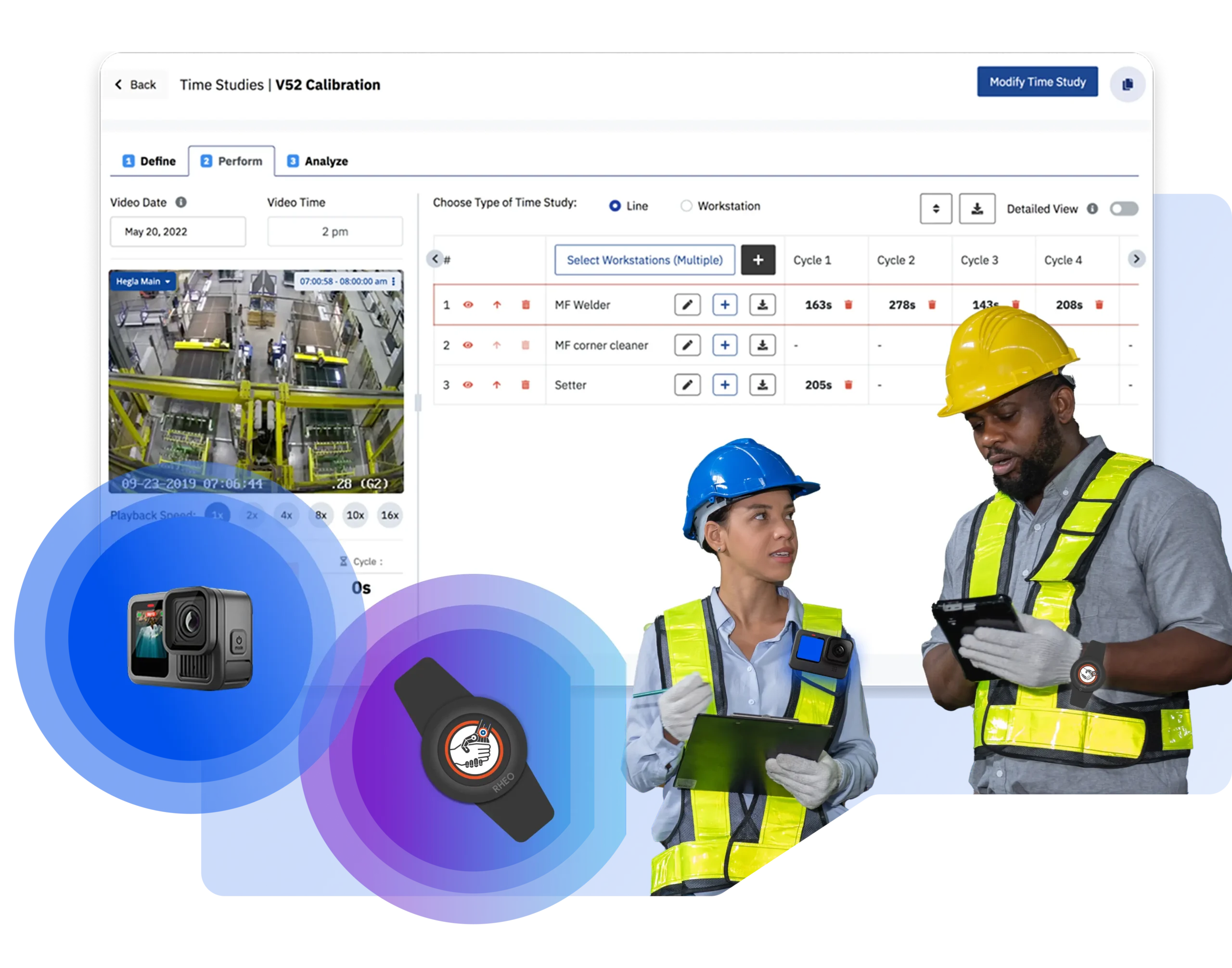

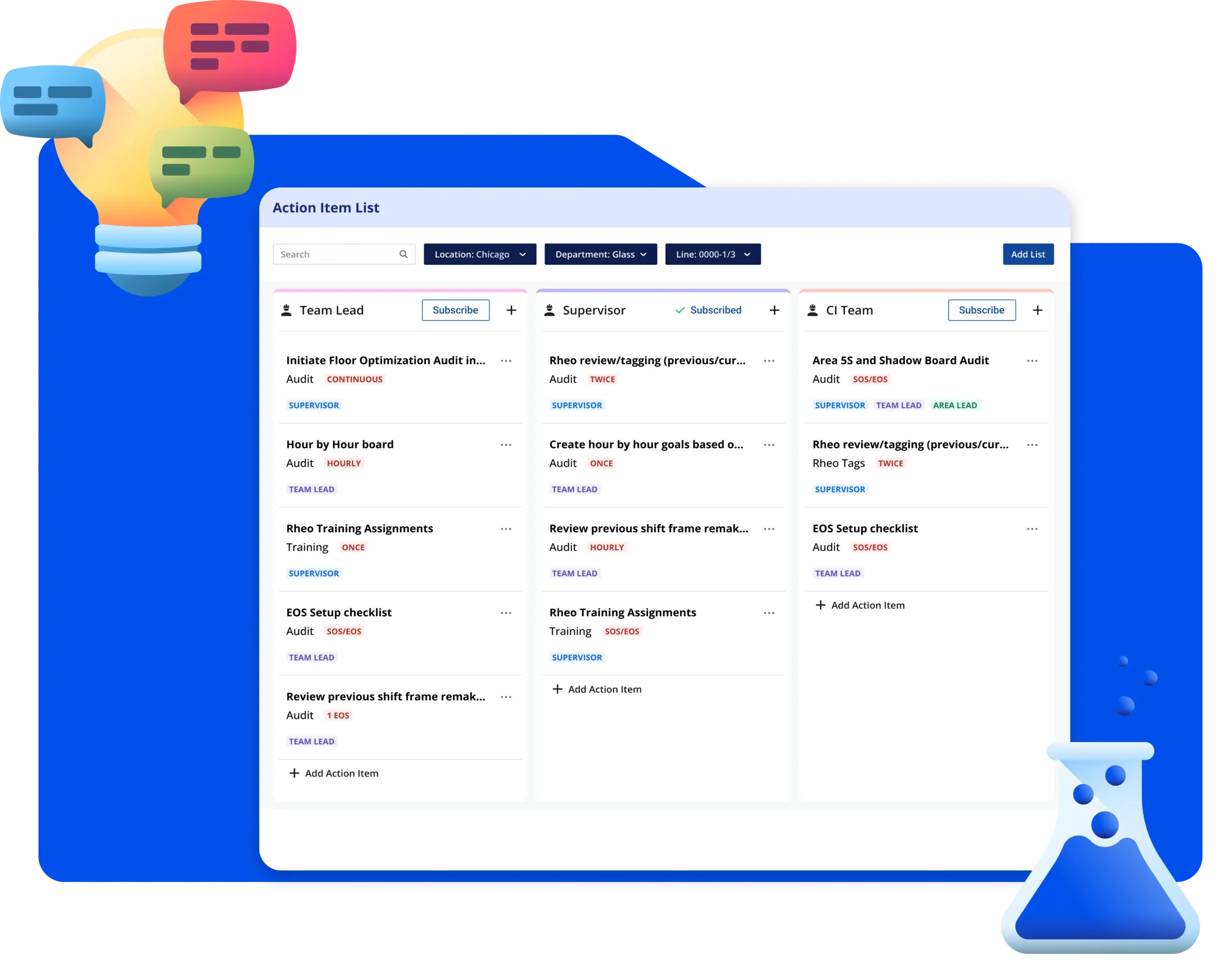

Rheo is a tool for Supervisors to perform Improvements rather than just the Continuous Improvements (CI) team. Further, CI Engineers can coach and train supervisors on how to make improvements on the line.

The result is bottoms-up idea generation from Supervisors, enabled by videos which provide transparency and continuous, incremental improvements.

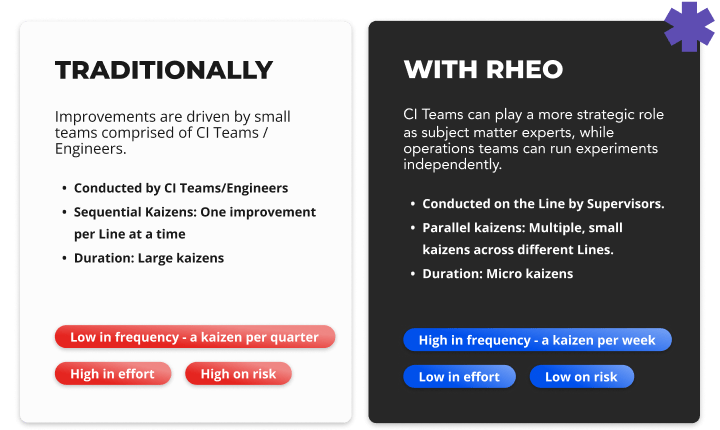

- Conducted by CI Teams/Engineers

- Sequential Kaizens: One improvement per line at a time

- Duration: Large kaizens

- Conducted on the Line by Supervisors.

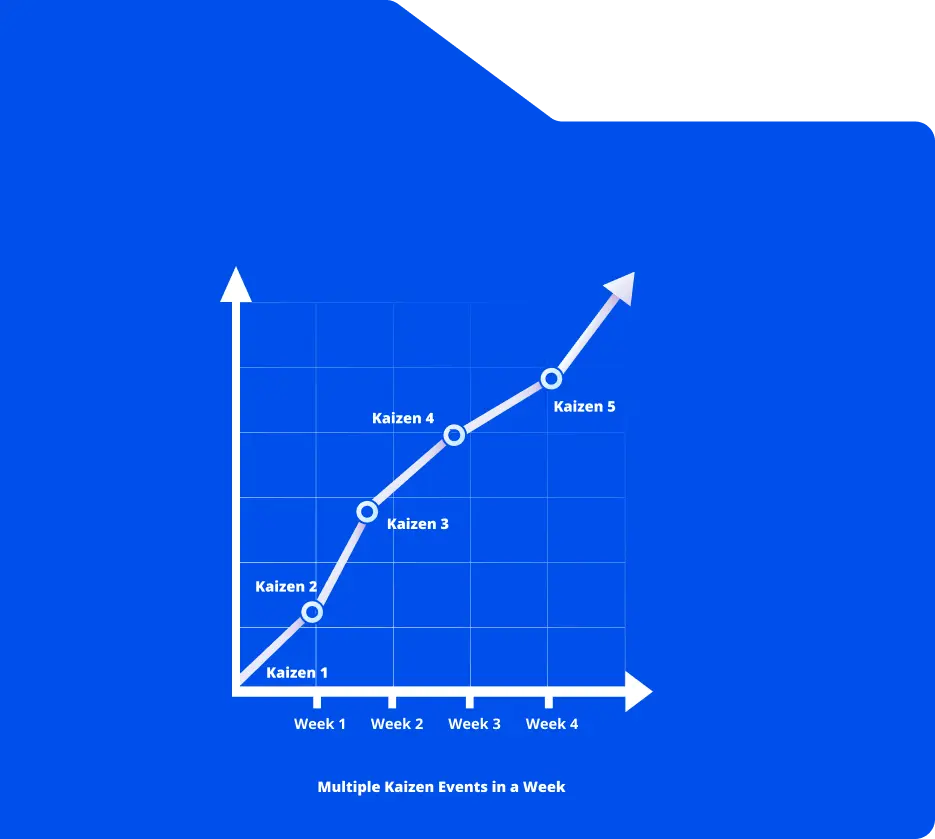

- Parallel kaizens: Multiple, small kaizens across different lines.

- Duration: Micro kaizens

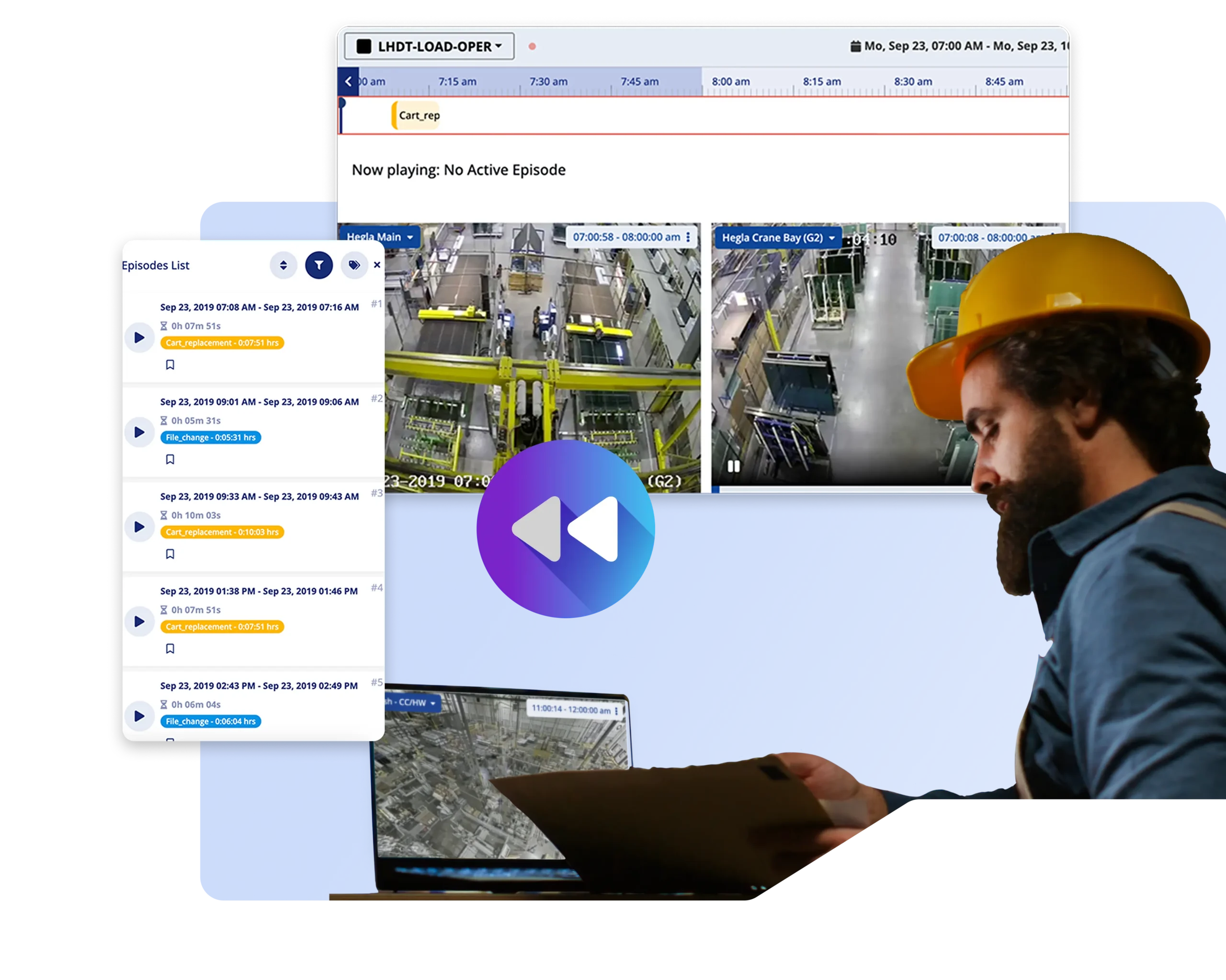

PLAYBACK

MODULE

studies

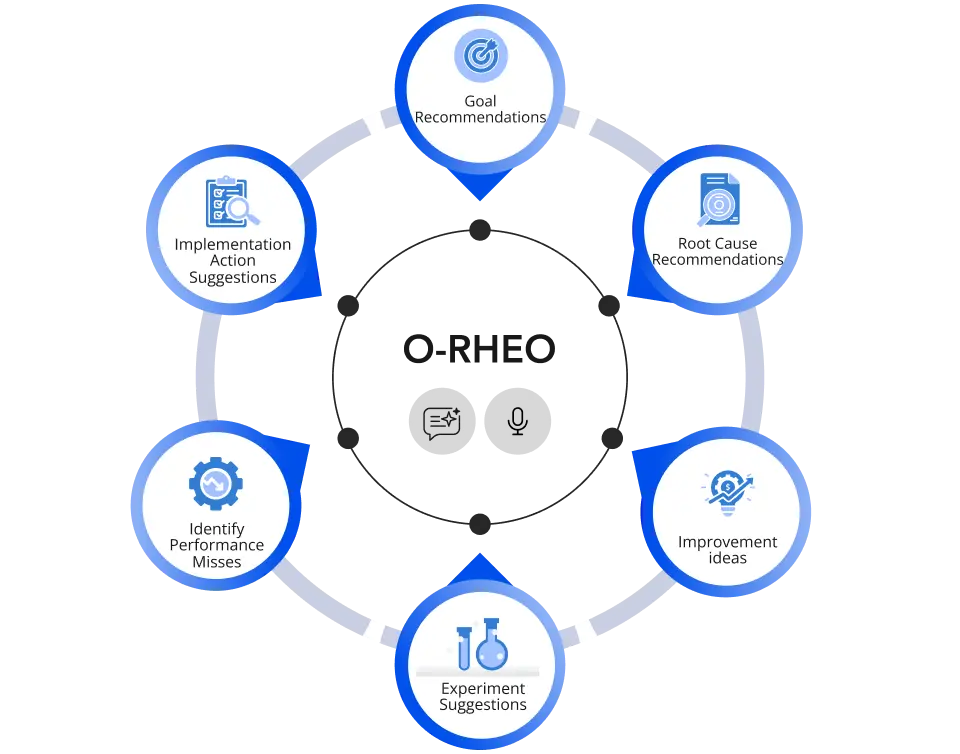

RECOMMENDATIONS

Automated Improvement Action Recommendations enable Supervisors to implement Improvements.

BENEFITS

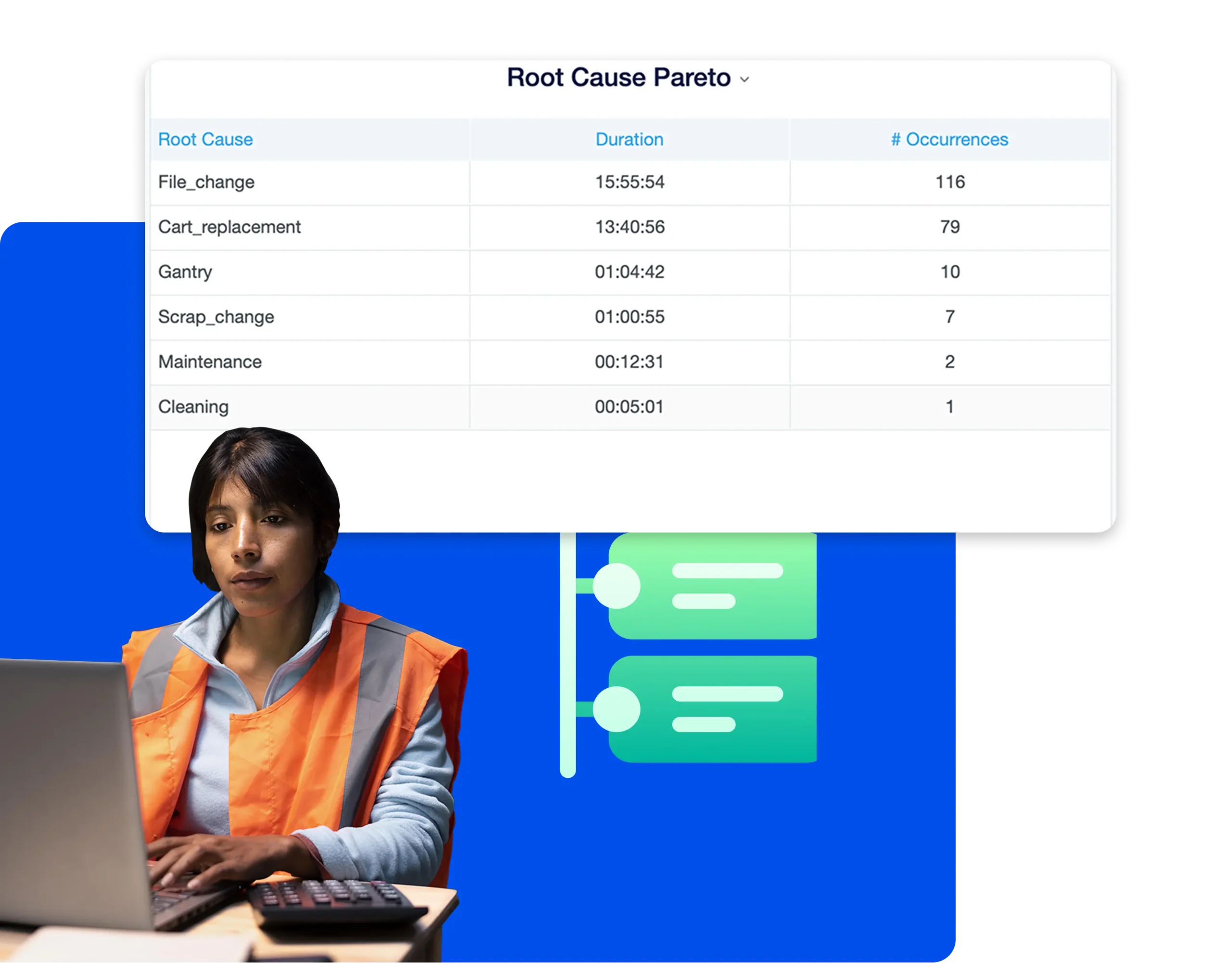

Root Cause Paretos

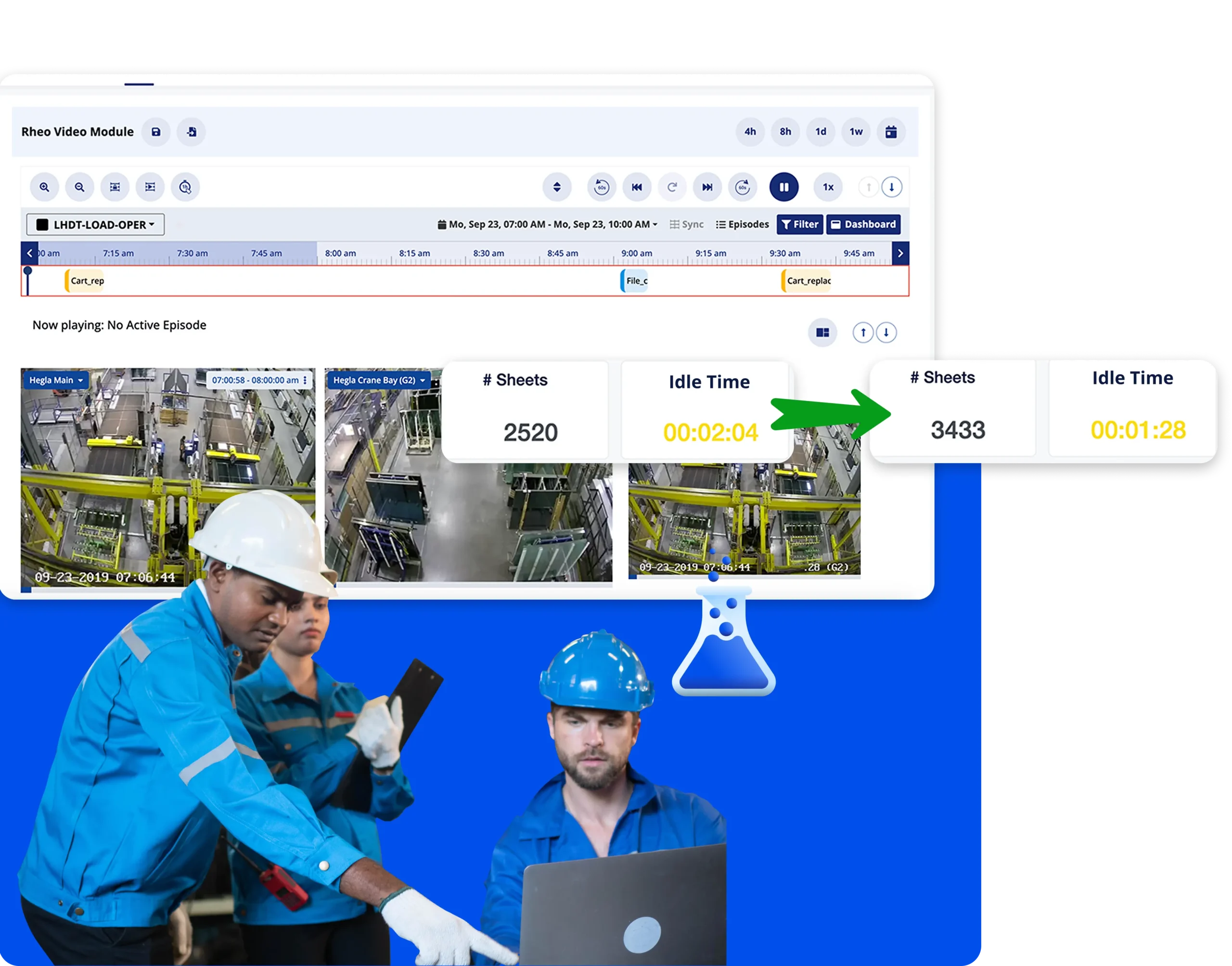

Experiments

Recommendations

with Video Playback

Tracking

Validate Experiments

Validate Experiments

Library

Library